HELLO HIVE

A warm welcome to my blog these new week, I hope you all had a refreshing weekend experience, I wish you all the best in all your endeavours this week, today I'll be taking you through the step by step process of how my apprentice made one of his first footwear, during a practice section where he get to put to practice all I've taught him in the past few months.

Though it's worthy of note that these projects as been down few weeks ago, but I've been unable to publish it due to my tight schedule from the new appointment, with that being said, come along as I show you the process of how my apprentice of 3 month made his second footwear during a practice section, which I also guide him on what and what is essential.

https://files.peakd.com/file/peakd-hive/vickoly/23x1abcXk2RqBSvQFCTSyjYUtnF9iuT4h69CRd45vXCLbNJS2b6593xDrPS9a4HbdhNgp.png

MATERIALS USED

- Suede Brown leather material

- Brown leather linning

- Marco size 4

- Nora

- Oci gum

- Shoe wet

https://files.peakd.com/file/peakd-hive/vickoly/23x1abcXk2RqBSvQFCTSyjYUtnF9iuT4h69CRd45vXCLbNJS2b6593xDrPS9a4HbdhNgp.png

MAKING PROCESSES

Being a novice with few knowledge in the craft of Shoemaking, I had to guide him as he made these palm Slippers, although he has watched me made something similar to these on several occasions in the past.

-

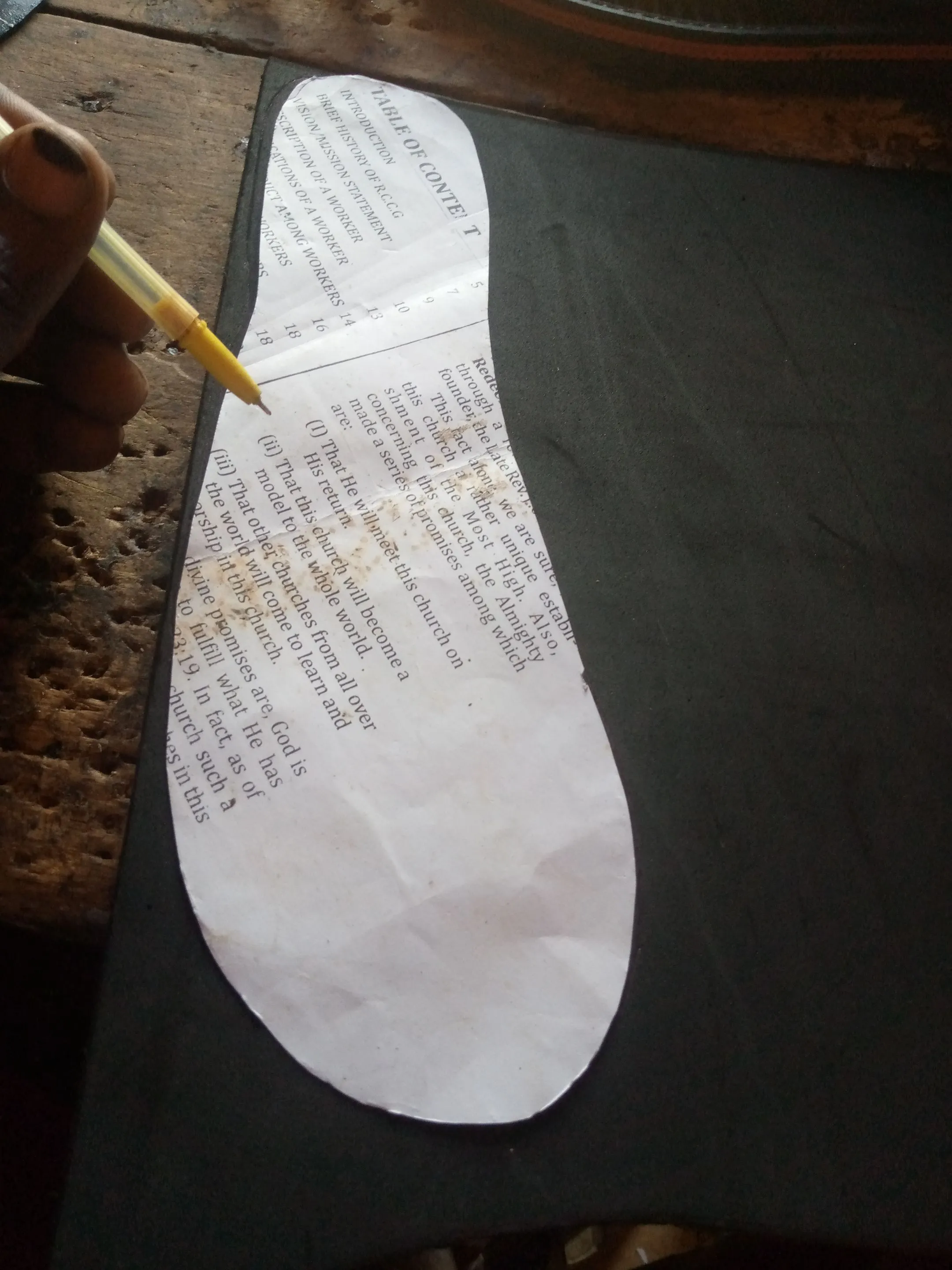

So yo make the slippers, I encourage him to cut a pattern pattern that will guide and as well make the shape of the slippers perfect.

-

After these, he then place the pattern on the Marco and the Nora materials meant for the insole and outsole of the slippers respectively, and then cut out the exact shape on each material.

- After these, he place the Marco material on a brown linning to cut out the shape, after which he rub gum on the Marco and linning and lastly wrap the linning around it.

- For the outsole, he merge two Nora together in other to have a firm and strong outsole, to do that he rub gum on another Nora and place the one he cut initially in step one on it, he then hit it with hammer and cut out the shape too.

-

I wasn't around by the time he started designing the upper of the slippers and by the time I came back he as already cut, join and sew the upper together.

-

So by the time I was back I met him joining the upper design of the slippers to the soles, and that process is called lasing/lasting in Shoemaking.

- These is the look of the palm slippers my apprentice of few month made, I know it's still practice and there are several errors, but with time he'll improve with commitment, seriousness and consistent practice.

https://files.peakd.com/file/peakd-hive/vickoly/23x1abcXk2RqBSvQFCTSyjYUtnF9iuT4h69CRd45vXCLbNJS2b6593xDrPS9a4HbdhNgp.png

Personally I've already stated his mistakes to him, which includes;

- The Designing of the upper

- The rough edges of the upper.

- The imperfect mode of lasting the shoe wet to the sole.

What's yours opinion and what do you think he can improve on from the sight of these slippers he made?

I believe with all these key point worked worked on, then he's certainly on his way towards excelling in this trade and as well earning massively from it.

Return from THE PROCESS OF HOW MY APPRENTICE MADE HIS FIRST FOOTWEAR to vickoly's Web3 Blog