#####

Happy new week to everyone in this lovely Community, it's so funny how time flies, within a blink of an eye, another Monday is upon us, though last week as been great until I feel sick, and after struggling with the illness throughout the weekend, I had no choice than go for a medical checkup, so as to ascertain what's wrong, and as well know what to take so I can get back to a perfect state of health.

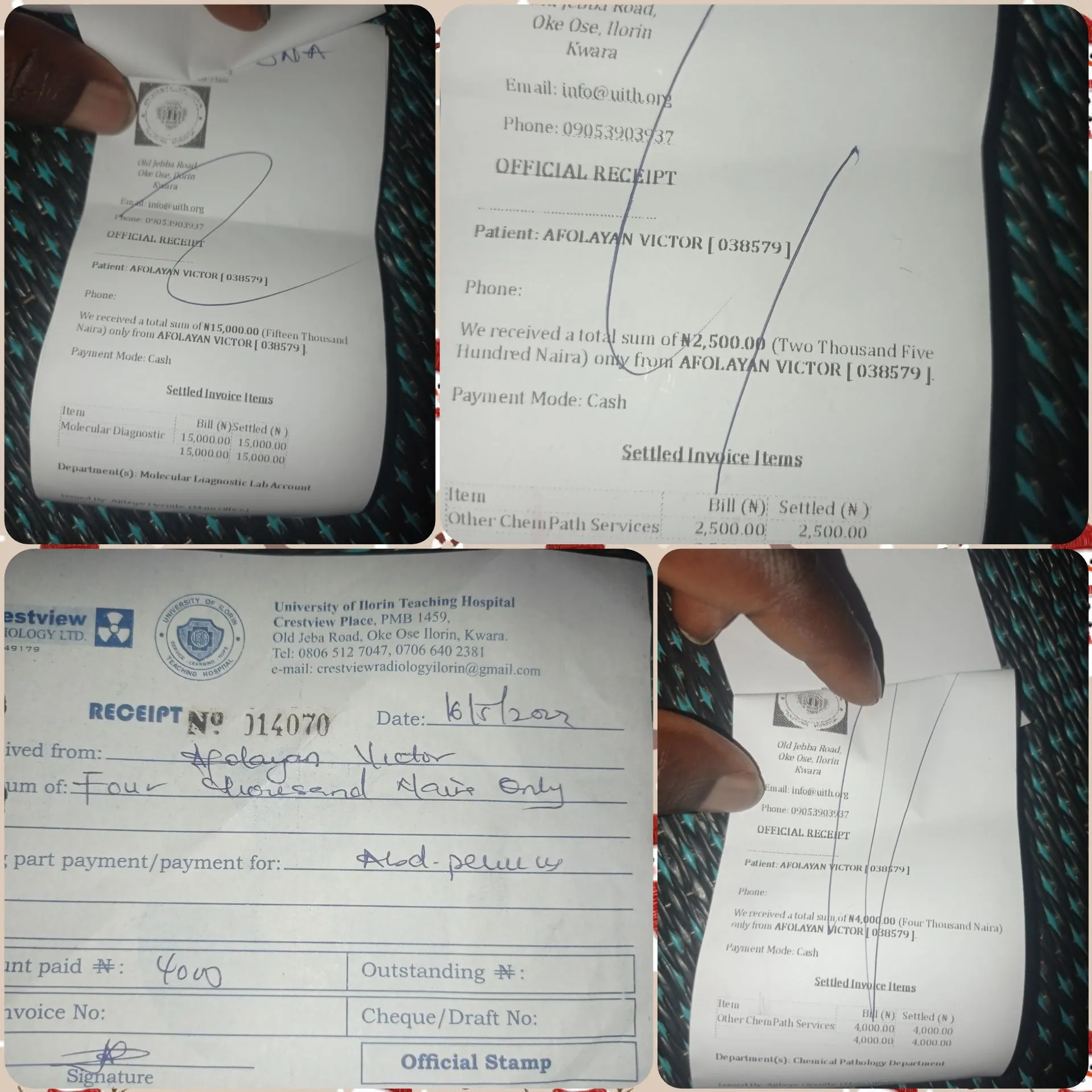

Base on the history of my health status, after communing with the doctor, he wrote some Series of test I should do, and before I knew it, over $50 as been spent on those tests, it's disheartening because that even more than the minimum wage paid to civil servant in my country, but then like it's commonly said "health is wealth", so I had no choice than to take care of myself.

Well not to bore you with my health status, this Slippers was the last project I was working on when I felt the illness, but then I wave it off thinking it's just the cold breeze that cost it, so the Slippers was made for a client who is never please with anything you make for him.

It may seems funny or like I'm over reacting, but I've never made a footwear for him, without him having at least 3 complain about the project, and the funny thing is that; several times when he came and saw other customers project I made, he'll admire it and say they're just perfect, he might ask for something like that, but once I made his, he'll have 1000 and 1 reasons why his isn't as good as the one he saw.

So most time he patronise me, I always try to put on an extra garment of patience, or else if one decide to speak, I might say something bad, that might chase him away, and I don't think such is good for any business.

So below are the materials and process of how I made this slippers.

MATERIAL USED

- Shining suede material

- Marco size 6

- Polyurethane Soles

- Gum

- Linning

- super Glue

PROCESSES

After buying the needs materials, I placed the sole on the marco material, to shape out the insole, cut and then attach it to the linning material.

Then I cut the upper with a paper pattern that I initially cut, then I attach it to the linning and join that together too.

- I sewed the edges of the upper and then attach the logo to it.

- I rub gum on all the parts of the slippers and join the upper to the insole together.

- Finally I rub gum on the insole and outsole and then join them together.

- And here is how gorgeous the Slippers looks like by the time I got through with it.

And like always, the alleged client still complain about several parts of the slippers, but since I'm accustomed to his behaviours, I didn't say a word that apologies and promise to do better next time.

Return from DEALING WITH A NEVER PLEASED CLIENT DESPITE BEING SERIOUSLY ILL to vickoly's Web3 Blog